Composite Project & Manufacturing Consulting

Allaz Futura supports companies across the full composite lifecycle — from early concepts and prototypes through tooling, assembly, and production readiness. My role is to bring experience, structure, and practical solutions to complex composite projects, whether as short-term support or integrated project assistance.

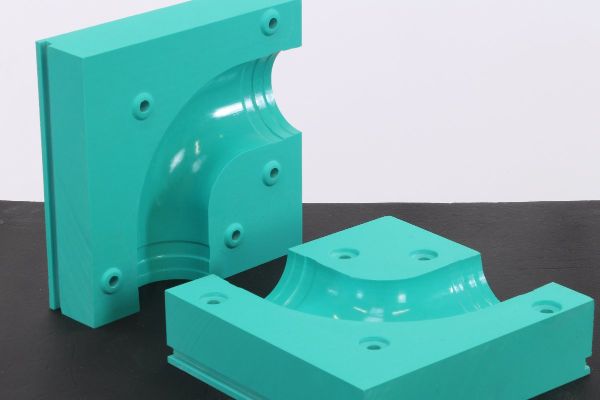

Tooling & Process Engineering

Development and optimization of tooling and manufacturing processes with a focus on reliability, repeatability, and cost control.

Typical scope:

- Tooling board and carbon tooling development

- Mold split strategy and build approach

- Layup and curing process optimization

- Assembly jig selection and precision techniques

- Process robustness and scrap reduction

Value for clients:

More stable processes, improved part quality, and better predictability in manufacturing.

Composite Prototyping & Small Series

Support for rapid development and controlled transition from prototype to pre-series and small-batch production.

Typical scope:

- Prototype build support

- Manufacturing methods definition

- Layup planning and documentation

- Pre-series and small-series setup

- Production readiness reviews

Value for clients:

Faster development, reduced iteration loops, and fewer surprises when moving toward production.

Services

For a full scope of services, please contact me to discuss your specific project and explore the most effective way to work together.